Operation

The user script file that runs on the device is named ‘init.js’. The file can be edited and downloaded to the device from the Scripting page on the Senquip Portal.

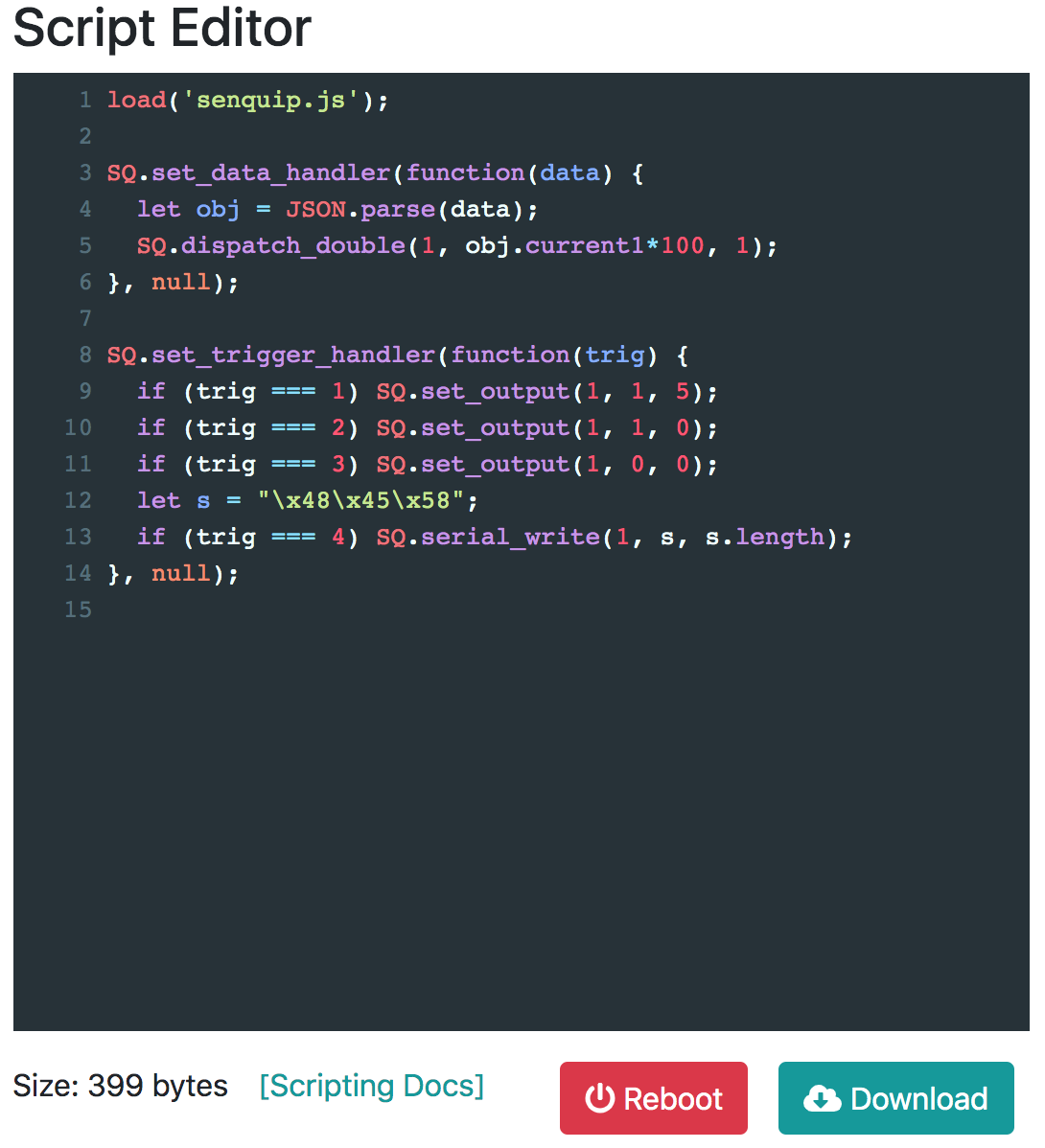

Scripting Window

After making changes on the Portal editor, press the Download button to send the script to the device via the command queue. Once the script has been successfully downloaded, the Reboot button can be used to restart the device and run the new script.

To optimise and reduce the size of the script, comments and leading/trailing white space is removed before the script is sent to the device.

Note

The total script size must be less than 20000 bytes

Script Execution

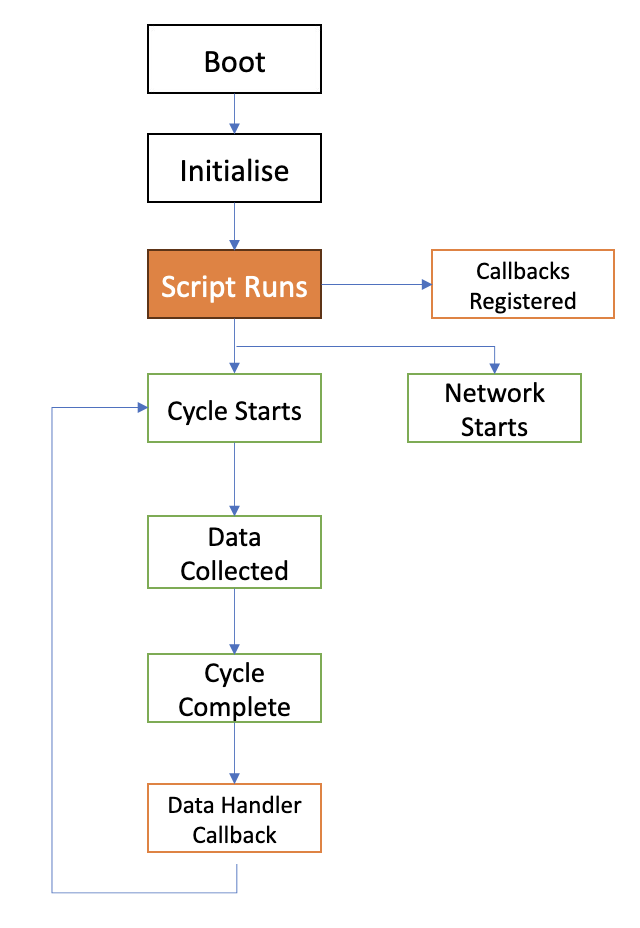

The script runs on the device every time the device boots, including when the device wakes from sleep. There is a single shared processor thread for script execution and other (critical) device functions. Therefore the script cannot block for long periods of time and should not contain infinite loops. It is also important to note that there is no network connection available during the initial script execution.

Script Execution Flowchart

In order to process data as it’s collected by the device or to trigger events, various callback functions can be registered by the script. These callback functions are then invoked when the device completes a measurement cycle, or a button is pressed from the Senquip Portal. See the Examples section for specific implementation details.

Custom Data Parameters

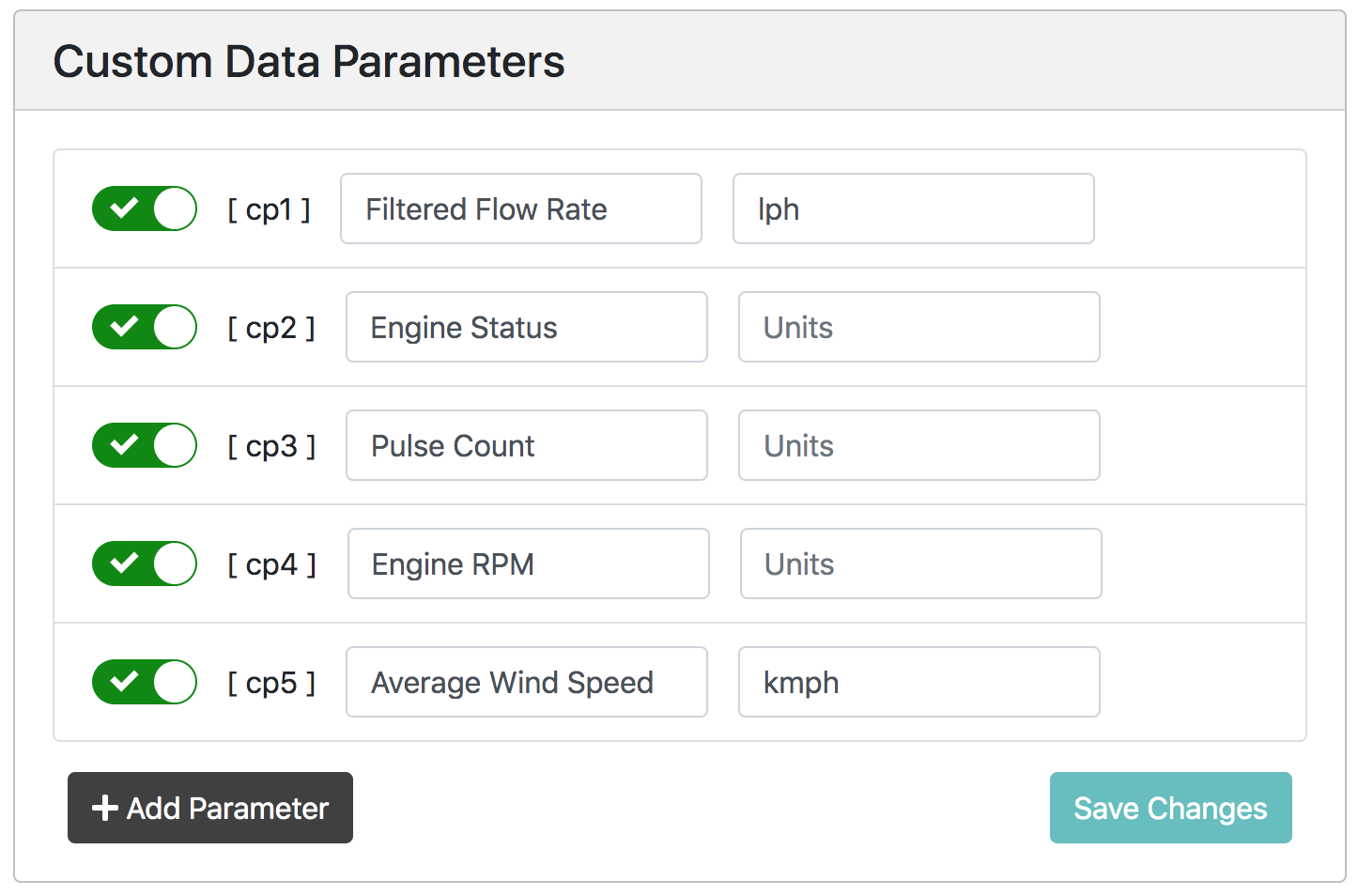

Custom data parameters are configured for the device in the window under the script editor. The visibility, name and units for each custom parameter (cp) can be modified. A parameter’s value can be sent in a data message as either a number (using dispatch_double()) or a string (using dispatch_string()). See examples section.

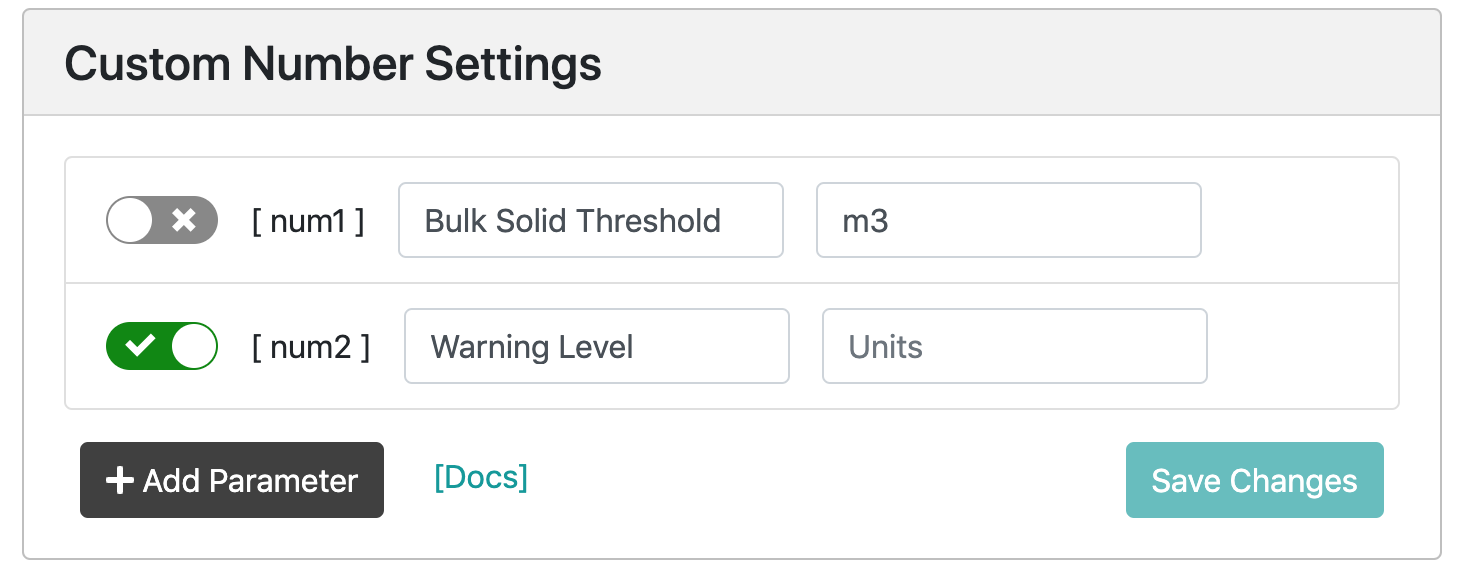

Setup of custom parameters

Trigger Parameters

Warning

Triggering actions on the device must not be used for safety critical applications. The system connected to the Senquip device must tolerate network delays and malfunction.

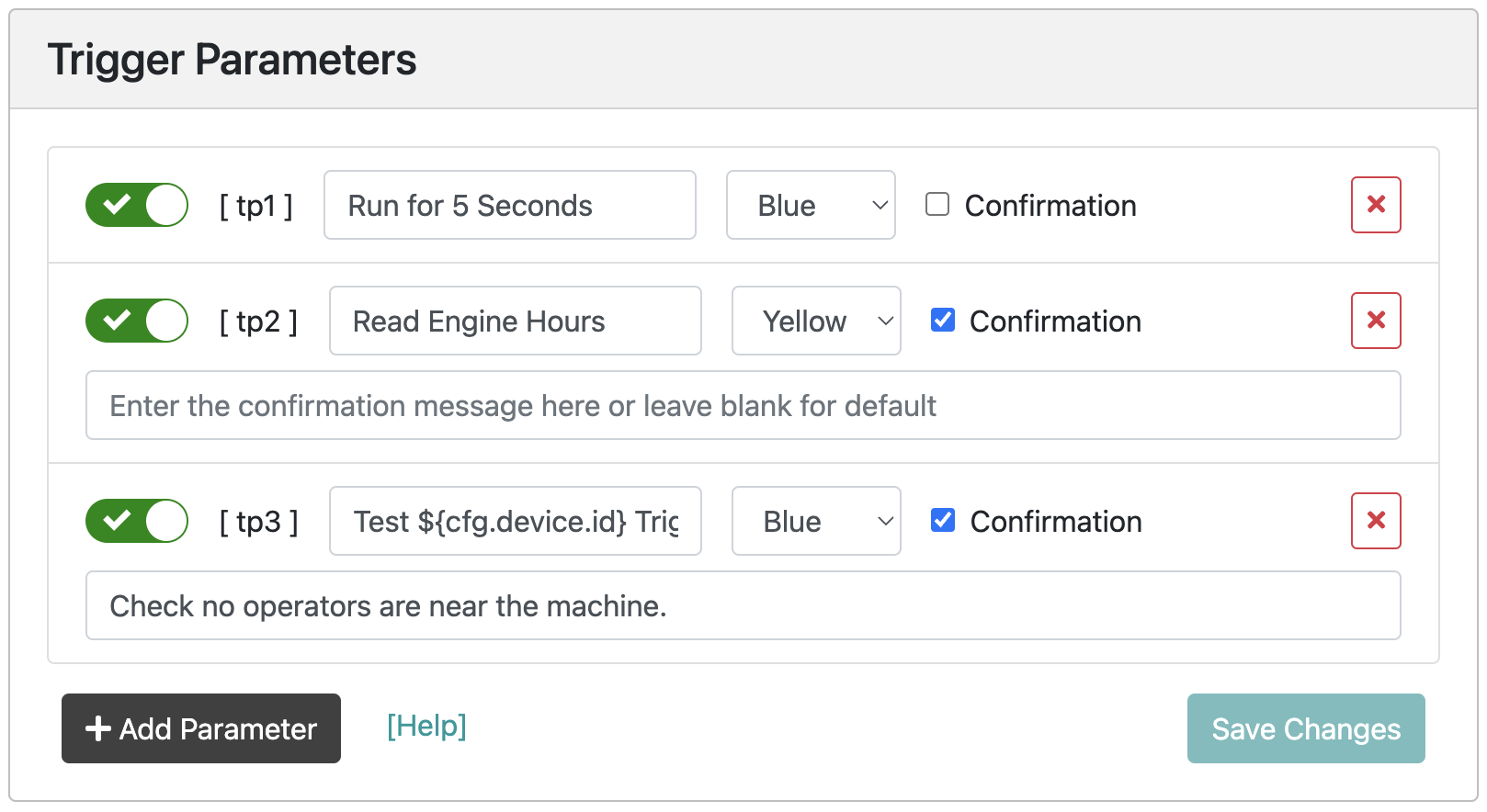

Each trigger parameter added will create a button on the main data page of the Senquip Portal. The name of the button and the colour can be customised. When a user clicks a button from the device’s home page, a command is queued and then sent to the device. When the device receives the command, a trigger callback function is invoked and the index of the trigger parameter is passed in. See examples section for specific details.

The name of the trigger can include dynamic text by using the format ${cfg.key}. The key can be any configuration key from the device, for example: ${cfg.device.name} or ${cfg.script.str1}. Refer to the List of Configuration Keys section.

A custom confirmation message can also be enabled for each trigger parameter. When enabled, the a confirmation message will be shown to the user after the button is pressed.

Setup of trigger parameters

Note

Triggering an action on the device does not provide feedback on the effect of the action. It is highly recommended the device is setup to monitor a physical parameter that will indicate if the trigger was successful or not. For example: if the trigger turns a pump on, monitor for changes in flow rate.

Custom Settings

Custom settings can be enabled for use by the script. These settings are permanently stored in the device’s FLASH memory like all other configuration values. Settings can either be a number or string type. The visibility, name and units for each custom setting can be modified from the Scripting page.

Setup of custom settings

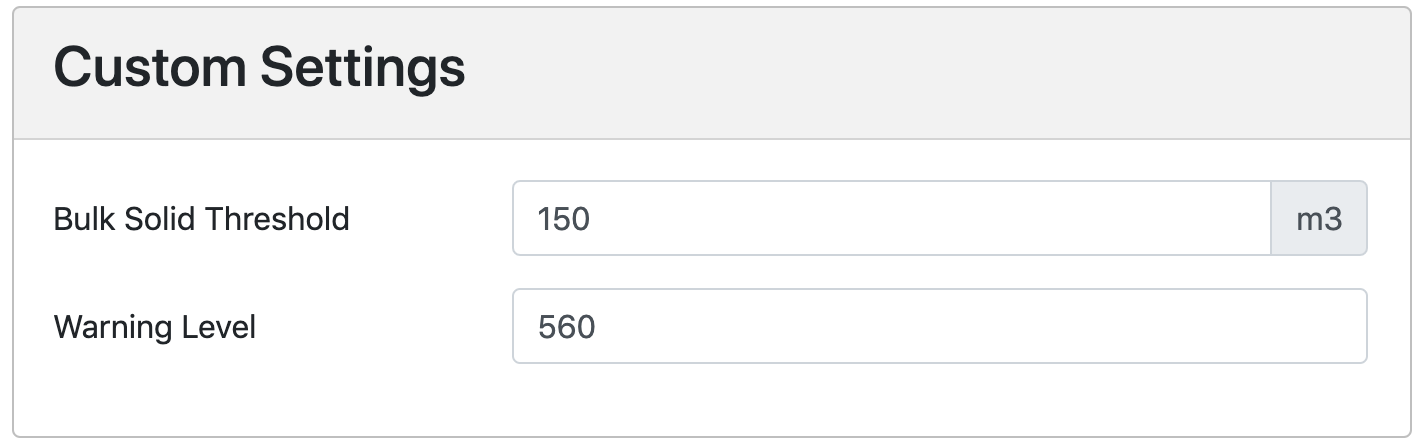

Once settings have been configured and enabled from the Scripting page, they will show up under the device’s Setting page on the Custom tab.

Use of custom settings

Note

When a user applies a change from the Settings page it causes the device to reboot, and the script to run again.

Settings can be set and read from the script using the Cfg.set(path) and Cfg.get(path) function calls. See examples section for more detail.

Warning

Excessive use of Cfg.Set() from the script will wear internal FLASH memory. The FLASH memory can typically endure 100 000 write cycles.

States

A common requirement for monitoring applications is knowing what ‘state’ a machine is in. The concept of machine states is built into Senquip devices. From the current measurement data a script can work out what state the machine is in, and record it accordingly using a single function call.

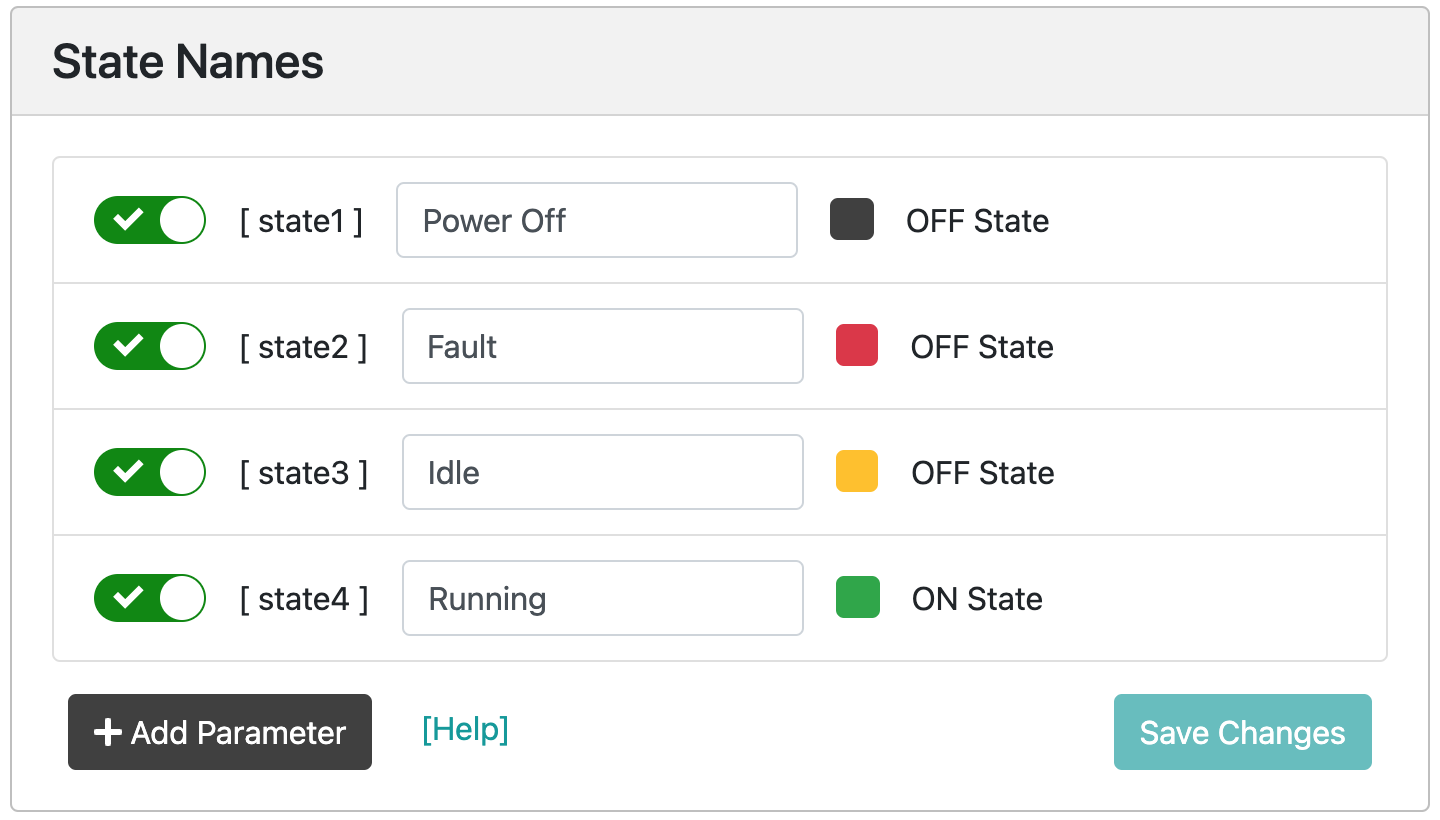

There are six custom states which can be named and used as required, plus a fixed ‘Offline’ state (state0). The hours spent in each state flows into the standard data message, allowing utilisation information to be calculated by an endpoint/dashboard. The names for each state can be set from the Scripting page, however the state colours are fixed.

Note: the names for each state are Senquip Portal settings only, the device and script do not use the custom names.

Setup of custom state names

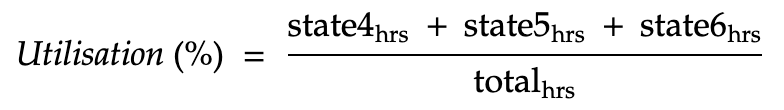

The last three states (4, 5 & 6) are considered ‘On’ or ‘Working’ states for utilisation calculations. Not all states need to be used, it depends on the application. At least one ‘ON’ state should be used if valid utilisation data is required. Utilisation on the Senquip Portal is calculated as follows:

Utilisation Formula

The state can be set from the script using the SQ.set_state(x) function call. Where X is the new state number. The device automatically records the number of hours spent in each state.

The hours recorded for a state can be reset to zero from the script using the SQ.hourmeter_set() function call. See reference section for usage.

By default the device always starts in State 0 (Offline) on reset.